When concrete slabs sink, creating tripping hazards and structural concerns, foam jacking foundation repair offers a revolutionary solution transforming how homeowners address settlement problems. This modern technology also known as polyurethane foam injection or polyjacking delivers faster, lighter, and more precise results than traditional mudjacking, making it the preferred choice for Richmond property owners facing sunken concrete issues.

The growing popularity of polyurethane foam lifting stems from remarkable advantages: lightweight materials won’t add stress to already-compromised soil, cures in minutes rather than days, and provides precision lifting impossible with heavier materials. This comprehensive guide explores everything Richmond homeowners need to know about foam jacking foundation repair—from understanding the technology and comparing it to traditional methods, to recognizing when it’s appropriate, understanding costs, and selecting qualified contractors delivering permanent solutions.

What Is Foam Jacking Foundation?

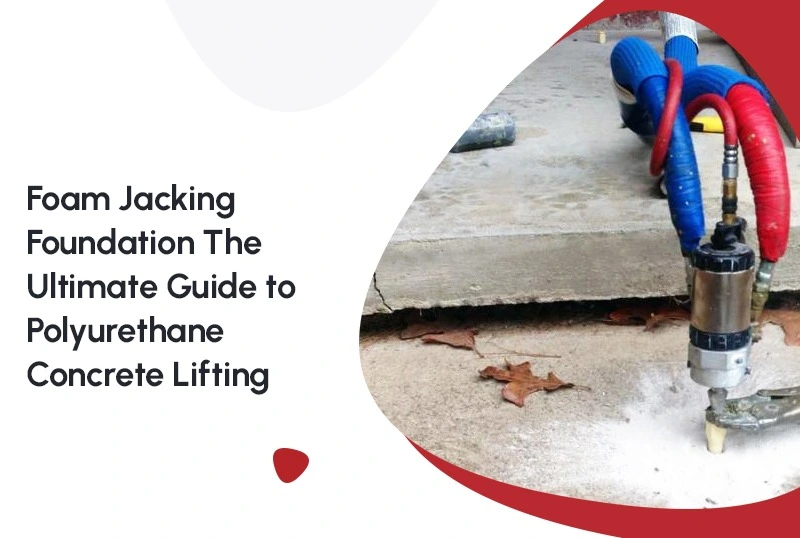

Polyurethane foam lifting represents an advanced concrete raising technology utilizing expanding foam to lift and level sunken slabs. The process involves injecting two-part liquid polyurethane beneath settled concrete through small penny-sized holes. Once injected, the liquid components mix and undergo a chemical reaction, expanding into rigid foam that fills voids beneath slabs while generating sufficient lifting force to raise concrete to desired elevations.

According to the American Concrete Institute, polyurethane foam technology delivers exceptional strength-to-weight ratios. The foam expands to approximately 20 times its liquid volume, creating rigid cellular structures supporting substantial loads while weighing just 2-4 pounds per cubic foot—dramatically lighter than traditional concrete slurry used in mudjacking, which weighs 100+ pounds per cubic foot.

The process delivers remarkable precision. Contractors monitor slab elevation in real-time during injection, adding foam incrementally until achieving exact desired heights. This controlled approach prevents over-lifting while ensuring uniform support across entire slab areas. The foam cures within 15-30 minutes, allowing immediate use—a dramatic improvement over traditional methods requiring 24-72 hours before bearing weight.

Foam Jacking Foundation vs. Mudjacking

Understanding how polyurethane foam injection compares to traditional mudjacking helps homeowners make informed decisions:

Traditional mudjacking pumps heavy concrete slurry (cement, sand, and other aggregates) beneath slabs through 2-inch diameter holes. While effective, this method adds significant weight to already-compromised soil—potentially contributing to future settlement. The material requires 1-3 days curing before use and offers limited precision control, sometimes resulting in over-lifting or uneven results.

Polyurethane foam lifting addresses these limitations comprehensively. The lightweight foam weighs 98% less than concrete slurry, eliminating concerns about additional soil stress. Small 5/8-inch injection holes minimize surface damage and prove nearly invisible after patching. The 15-minute cure time allows immediate use, and precise injection control delivers accuracy within fractions of an inch.

Durability comparisons favor this technology. Polyurethane foam resists moisture, won’t wash out or erode like concrete slurry, and maintains structural integrity indefinitely. Traditional mudjacking materials may deteriorate over time from water infiltration or soil movement, potentially requiring re-treatment. For comprehensive information about different concrete lifting and leveling methods, read our detailed article on concrete slab repair techniques.

Cost considerations show polyurethane foam injection typically costs 25-50% more than mudjacking initially. However, superior durability, faster completion, immediate usability, and reduced re-settlement risk often make it the more cost-effective long-term solution. According to the U.S. Department of Energy, foundation improvements including proper leveling can enhance home energy efficiency by preventing air infiltration and moisture problems.

Benefits of Foam Jacking Foundation

Polyurethane foam injection delivers numerous advantages making it the preferred modern solution:

Lightweight Material

The minimal weight of polyurethane foam prevents additional soil stress. Traditional concrete slurry adds 100+ pounds per cubic foot to already-settled areas, potentially accelerating future problems. Polyurethane foam at 2-4 pounds per cubic foot eliminates this concern while delivering equivalent or superior lifting capacity.

Fast Curing and Minimal Disruption

Projects complete quickly with minimal disruption. The foam cures in 15-30 minutes, allowing immediate use of repaired surfaces. Small 5/8-inch injection holes require minimal patching and remain barely visible. Most residential applications complete in 2-4 hours total, compared to full-day or multi-day projects required for traditional methods.

Precision and Control

The controlled expansion allows precise leveling impossible with heavier slurries. Contractors monitor elevation continuously, adding foam incrementally until achieving exact specifications. This precision proves particularly valuable for applications requiring strict tolerances like garage floors, pool decks, or interior slabs where even slight variations cause problems.

Waterproof and Moisture-Resistant

Polyurethane foam resists water absorption and won’t deteriorate from moisture exposure. This waterproof characteristic prevents wash-out problems common with concrete slurry while simultaneously stabilizing soil beneath slabs by reducing moisture infiltration. The foam creates a moisture barrier protecting against future water-related settlement.

Environmental Considerations

Modern materials utilize environmentally responsible formulations. The foam contains no harmful chemicals, won’t leach into groundwater, and the minimal material volume reduces environmental impact compared to large concrete slurry quantities. Quick application reduces equipment operation time, lowering carbon footprint.

The Foam Jacking Foundation Process

Professional polyurethane foam lifting follows systematic procedures ensuring optimal results:

Initial assessment determines whether this repair method proves appropriate. Contractors evaluate slab condition, settlement extent, underlying soil characteristics, and void sizes beneath concrete. They identify settlement causes ensuring repairs address root problems. For properties experiencing foundation settlement requiring comprehensive solutions beyond slab lifting, professional foundation repair Richmond specialists coordinate foam injection with broader foundation stabilization.

Site preparation involves cleaning work areas and marking injection hole locations. Contractors determine optimal hole placement ensuring uniform foam distribution beneath slabs. Strategic hole positioning proves critical for effective results, preventing weak spots or uneven lifting.

Drilling and injection proceeds methodically. Contractors drill 5/8-inch holes through slabs at marked locations, then insert injection ports. They pump polyurethane foam beneath slabs, monitoring elevation and adjusting injection rates achieving desired lift. The process typically progresses from low areas to high, ensuring complete void filling and uniform support.

Completion and verification includes removing injection ports, patching holes with color-matched cement, and verifying final elevations meet specifications. Quality contractors provide documentation showing pre-repair and post-repair measurements, confirming work quality and warranty coverage.

Applications of Foam Jacking Foundation

Polyurethane foam injection addresses diverse concrete settlement problems:

Concrete slab foundations experiencing settlement benefit tremendously from foam lifting. The lightweight material raises slabs without adding stress while filling voids preventing future settlement. Interior slabs, garage floors, and basement floors all prove excellent candidates. For properties requiring comprehensive foundation leveling beyond localized slab lifting, professional house leveling service Richmond specialists integrate polyurethane foam techniques with broader stabilization methods.

Driveways, sidewalks, and patios represent common applications. Sunken concrete creates tripping hazards, drainage problems, and aesthetic concerns. Polyurethane foam injection restores proper grades quickly and economically compared to complete replacement. Pool decks particularly benefit from waterproof foam preventing water-related settlement recurrence.

Commercial applications include warehouse floors, loading docks, parking structures, and sidewalks. The fast cure time minimizes business disruption while lightweight material prevents additional stress to already-compromised soils. According to the National Association of Home Builders, proper foundation and slab maintenance including leveling proves essential for preserving property values and preventing more expensive repairs.

When to Consider Foam Jacking Foundation

Several indicators suggest foam jacking foundation repair may prove appropriate:

Visible settlement where concrete slabs sink creating uneven surfaces represents the primary indication for consideration. Sunken garage floors, settled driveway sections, or tilted patio slabs all qualify. Settlement ranging from 1/2 inch to several inches typically proves repairable through foam injection, though extremely severe cases might require alternative solutions.

Gaps and separations appearing between slabs and adjacent structures indicate settlement warranting evaluation. Gaps between garage floors and foundation walls, separated sidewalk sections, or pool decks pulling away from pools all suggest underlying support loss correctable through polyurethane foam injection.

When NOT to use this method: Severely cracked or structurally compromised slabs may require replacement rather than lifting. Active soil movement from ongoing water infiltration or poor drainage demands addressing underlying causes before slab repair. Properties with pier and beam foundations face different challenges requiring specialized approaches. For more information about elevated foundation systems and their unique repair requirements, read our comprehensive guide on pier and beam foundation repair Richmond solutions.

Foam Jacking Foundation in Richmond Homes

Richmond’s unique environmental conditions make polyurethane foam lifting particularly effective. The area’s clay soils expand when wet and contract during droughts, creating settlement problems this technology addresses exceptionally well. The lightweight material prevents additional soil stress while waterproof properties protect against moisture-related re-settlement.

Common Richmond applications include garage floor leveling following soil shrinkage beneath slabs, driveway repair where sections settle from erosion or poor compaction, and basement floor correction addressing water-related settlement. Professional foundation repair Richmond specialists understand local soil behavior and provide solutions accounting for regional challenges ensuring long-term success.

Cost of Foam Jacking Foundation

Understanding costs helps homeowners budget appropriately. Residential projects typically range from $3-$7 per square foot of lifted slab, with most applications costing $1,200-$4,500 total. Factors affecting price include settlement severity, slab thickness, accessibility, and total area requiring treatment.

While polyurethane foam injection costs more initially than mudjacking ($2-$5 per square foot), superior durability, faster completion, and reduced re-settlement risk deliver better long-term value. Compared to complete slab replacement costing $6-$15+ per square foot, foam lifting proves highly economical. The investment protects property values, eliminates tripping hazards, and prevents water infiltration problems from uneven surfaces.

Choosing a Foam Jacking Foundation Contractor

Selecting qualified contractors ensures successful outcomes. Verify contractors possess specific polyurethane foam injection experience rather than just general concrete work. Quality equipment proves essential—professional-grade foam injection systems deliver superior results compared to entry-level equipment.

Request references from recent projects and verify completion quality. Seek comprehensive warranties covering both materials and workmanship for 5-10+ years. Obtain multiple detailed estimates specifying foam types, lifting guarantees, and warranty terms. Professional foundation repair Richmond specialists should explain exactly how they’ll address your specific settlement problems and prevent recurrence.

Maintenance After Foam Jacking Foundation

Following repair, minimal maintenance proves necessary. The foam requires no special care and performs indefinitely under normal conditions. However, addressing underlying settlement causes prevents future problems. Maintain proper drainage directing water away from slabs. Repair plumbing leaks promptly. Monitor soil moisture during droughts preventing excessive shrinkage.

Periodic inspection ensures repairs remain effective. Check annually for new settlement, cracks, or separation. Most quality installations remain stable indefinitely, but monitoring catches any developing problems early. Reputable contractors provide warranty coverage addressing rare issues, offering peace of mind that investments remain protected.

Conclusion: Modern Solution for Concrete Settlement

Foam jacking foundation repair represents the evolution of concrete lifting technology—delivering faster, lighter, more precise, and more durable results than traditional methods. The advantages of polyurethane foam injection—minimal weight preventing additional soil stress, rapid 15-minute cure time allowing immediate use, precision control enabling exact leveling, and waterproof properties preventing moisture-related problems—make it the superior choice for addressing sunken concrete.

For Richmond homeowners facing settlement challenges, this technology provides effective solutions accounting for local soil conditions and climate factors. Whether addressing garage floor settlement, sunken driveways, tilted patios, or basement floor problems, polyurethane foam injection delivers permanent repairs protecting property values and eliminating safety hazards.

Don’t let sunken concrete deteriorate into expensive replacement projects. If you’ve discovered settlement affecting your property, professional evaluation determines whether polyurethane foam injection provides the optimal solution. Qualified foundation repair Richmond specialists can assess settlement severity, identify underlying causes, and recommend comprehensive solutions delivering permanent results.

Your property deserves modern technology delivering superior outcomes. Whether you need localized slab lifting or comprehensive foundation solutions, expert foam jacking foundation services ensure professional results backed by warranties protecting your investment. Schedule your evaluation today—discover how polyurethane foam technology transforms sunken concrete problems into level, stable surfaces supporting your property for decades to come.

Frequently Asked Questions

What is foam jacking foundation?

Foam jacking foundation is a modern foundation repair method that uses high-density polyurethane foam to lift and stabilize settled concrete slabs. This innovative technique involves injecting expanding foam beneath the foundation through small holes, which then expands and hardens to provide support. Unlike traditional methods like mudjacking, foam jacking foundation repair offers superior durability and precision. The polyurethane foam is waterproof, lightweight, and permanent, making it an excellent choice for addressing foundation settlement issues while minimizing disruption to your property.

Why choose foam jacking foundation for foundation issues?

Foam jacking foundation offers numerous advantages over traditional repair methods. The process is minimally invasive, requiring only small injection holes that are easily concealed afterward. Foam jacking foundation provides immediate results with precise lifting control, allowing technicians to raise slabs to exact specifications. The polyurethane foam is environmentally friendly, waterproof, and won’t wash away like traditional materials. Additionally, the lightweight nature of the foam won’t add extra burden to underlying soils, and the quick curing time means your foundation is ready for use within hours rather than days.

How does foam jacking foundation work step by step?

The foam jacking foundation process begins with a thorough assessment of the settled areas and soil conditions. Technicians drill small holes, typically 5/8-inch in diameter, through the concrete at strategic locations. High-density polyurethane foam is then injected beneath the slab through specialized equipment. The foam jacking foundation technique relies on the foam’s expansion properties to fill voids and lift the concrete gradually. As the foam expands and cures, it creates a stable base. Finally, the injection holes are sealed with concrete, leaving minimal visible evidence of the repair work completed.

When should I consider foam jacking foundation?

You should consider foam jacking foundation when you notice signs of concrete settlement such as uneven floors, cracks in walls, doors that don’t close properly, or visible gaps around your foundation. This method is ideal for addressing sunken driveways, sidewalks, patios, and foundation slabs. Foam jacking foundation is particularly beneficial when you need quick results without extensive excavation or when traditional methods aren’t suitable for your soil conditions. It’s also an excellent preventive measure to address minor settlement before it becomes a major structural problem requiring more expensive solutions.

Can foam jacking foundation fix all foundation problems?

While foam jacking foundation is highly effective for many issues, it cannot solve all foundation problems. This method works best for concrete slab settlement, void filling, and soil stabilization beneath existing structures. Foam jacking foundation is excellent for addressing problems caused by soil consolidation, erosion, or poor compaction. However, it may not be suitable for severely damaged foundations with extensive cracking, structural failures, or foundations that require complete replacement. For complex structural issues or deep foundation problems, alternative methods like underpinning or complete reconstruction might be necessary for proper resolution.

What does foam jacking foundation cost?

The cost of foam jacking foundation varies depending on several factors including the size of the affected area, extent of settlement, and local market conditions. Generally, foam jacking foundation repairs cost more initially than traditional mudjacking but offer better long-term value due to their permanence and durability. Typical costs range from $300 to $600 per area, though extensive projects may have different pricing structures. The investment is often justified by the method’s longevity, minimal disruption, and quick completion time. Most contractors provide free estimates, allowing you to compare foam jacking foundation costs with alternative repair methods.

Is foam jacking foundation a long-term solution?

Yes, foam jacking foundation provides an excellent long-term solution for foundation settlement issues. The high-density polyurethane foam used in this process is designed to last indefinitely without degrading, unlike organic materials that may decompose over time. Foam jacking foundation repairs typically come with warranties ranging from 5 to 10 years, demonstrating contractor confidence in the method’s durability. The foam’s waterproof properties prevent washout, and its chemical stability ensures it won’t break down under normal conditions. When properly installed by qualified professionals, foam jacking foundation can provide decades of reliable support for your structure.